HOW TO FORM THE GLASS,come si forma il vetro

CENNI DI STORIA DEL VETRO DI MURANO

A cavallo tra il duecento e il trecento, le importanti casate nobiliari europee commissionano alle vetrerie veneziane oggetti domestici in vetro come bicchieri ed ampolle. L’esercizio di questa

arte in questo periodo è concentrato a Murano lungo il Rio dei Vetrai, dove ancora oggi si trovano le fornaci più antiche.

Dal 1450, grazie anche al contributo di Angelo Barovier, vetraio di una delle famiglie più antiche di Murano, a Venezia avviene una vera e propria rivoluzione tecnologica che permette alla città di

intraprendere uno sviluppo eccezionale nel corso dei due secoli successivi.

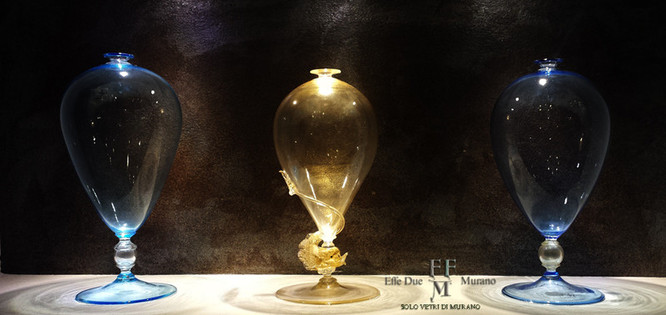

Il vetro creato da Barovier si contraddistingue per l’elevata purezza, per le somiglianze al cristallo di roccia, talmente incolore e terso da essere denominato “cristallo”. Altre invenzioni

attribuibili a Barovier sono il *”lattimo”, un vetro bianco opaco simile alle porcellane cinesi ed il *”calcedonio”, una pasta vitrea molto simile ad una varietà del calcedonio naturale. E’ però nel

XVI secolo che la storia del vetro di Murano conosce il suo massimo splendore.

A BRIEF HISTORY OF MURANO GLASS

Straddling the two

hundred and three hundred , the important noble families to the European commission Venetian glassware household items such as glasses and glass ampoules . The exercise of this art in this period is

concentrated along the Murano Glass Merchants of Rio , where even today you will find the oldest kilns .

Since

1450 , thanks to the contribution of Angelo Barovier , glazier of one of the oldest families of Murano, Venice takes a real technological revolution that allows the city to undertake a dramatic

development during the next two centuries .

The glass created by

Barovier is characterized by high purity, for the similarities in rock crystal , colorless and clear so as to be called "crystal" .

Other inventions attributed to Barovier * are the " milky " , a white opaque glass similar to Chinese porcelain and * " chalcedony " , a glass paste very similar to a variety of natural chalcedony

. And ' in the sixteenth century , however, that the history of Murano glass enjoyed

its greatest splendor.

Per ottenere il liquido, il fuso, che solidificando avrà le caratteristiche

del vetro, si parte da materie prime che, per il 70 % in peso circa,

sono costituite da sabbia (silice). Si può dire che il vetro è fatto

sostanzialmente di silice, chiamata perciò "vetrificante", le altre

materie prime essendo aggiunte per ottenere un liquido a temperature

non troppo elevate: 1400°C circa per l'attuale vetro muranese, mentre

la silice, da sola, si trasforma in liquido a temperature superiori ai

1700°C. Le sostanze che consentono di ottenere un liquido a

relativamente basse temperature vengono chiamate "fondenti".

Il fondente tipico è la soda. L'ossido di sodio presente nel vetro

modifica notevolmente le caratteristiche del vetro ottenuto.

In particolare la lavorabilità e la resistenza chimica della superficie.

Tanto maggiore è la quantità di sodio presente nel vetro e tanto più di

vetro solidifica "lentamente" (si dice che il vetro è "lungo"). Per la

lenta lavorazione manuale, sarà necessario che il vetro sia

sufficientemente lungo, e contenga quindi abbastanza sodio.

La quantità di sodio non deve però essere eccessiva altrimenti il vetro

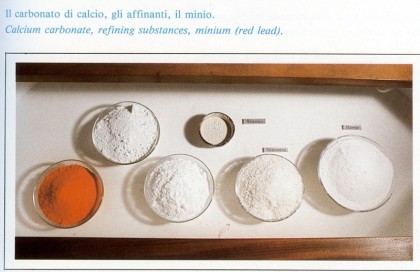

opacizza in superficie per azione dell'umidità atmosferica. Per limitare

la tendenza all'opacizzazione viene impiegato il calcare o carbonato di

calcio. Anche il calcio abbassa la temperatura alla quale si ottiene il

liquido fuso ed è quindi un fondente, ma poiché inoltre limita la

tendenza alla opacizzazione viene chiamato "stabilizzante", in quanto

rende stabile la superficie del vetro nei confronti dell'umidità

atmosferica. Per avere un vetro sodico che conservi nel tempo le sue

caratteristiche di trasparenza è necessaria quindi una certa quantità di calcio.

Altre materie prime che si aggiungono alla miscela vetrificabile

costituita da silice, soda e calcare, sono il nitrato e l'arsenico che

hanno azione "affinante", cioè facilitano la fuoriuscita delle bolle dal

fuso e migliorano l'omogeneità. Con queste materie prime si ottiene il

vetro trasparente incolore, chiamato, fin dal 1450 circa, "Cristallo

muranese". Se alle materie prime indicate vengono aggiunte piccole

quantità di sostanze coloranti od opacizzanti, si ottengono i vetri

colorati o i vetri opali.

TECHNOLOGY AND TRADITION

IN MURANO GLASSMAKING

Tullio Toninato

On the 20th oj December, 982, Dominicus "fiolarius", that is, maker

of phials or glass ampoules, signed a document donating the Church

oj San Giorgio on the island oj the same name, in Venice, to

Giovanni Mauroceno.

This is the oldest document attesting to glassmaking activities in the

Venetian lagoon, activities that are thought to have their origin well

back in history and certainly bejore 982, and, that were to gain so

much jame and prosperity in successive centuries.

On the occasion oj the thousand year anniversary oj the donation, an

exhibition was set up in rooms oj the Ducal Palace and the Correr

Museum. It celebrated "A Thousand Years oj Glassmaking in

Venice". Included in this exhibition there was a technical section,

arranged by the Stazione Sperimentale del Vetro in Murano, with the

aim oj illustrating the most ancient Muranese glass production and

present day working techniques.

The text which jollows has been, in fact, taken jrom the exhibition

catalogue by Albrizzi published in Venice, as indeed the photographs

enclosed which are oj material displayed in the exibition.

The specific jeature of glass, the one which distinguishes it jrom other

materials, metals jor example, is the way in which it solidifies, that is,

how it passes jrom the liquid state at high temperatures (l400°C jor

present-day Murano glass) to the rigid-solid state. Solidification in

glass takes piace slowly as the temperature decreases. It passes jrom

the fluidity of the melted substance with ever-increasing viscosity to

the rigidity oj the solid at about 500°C. It is in this interval, called in

jact the working time, when the glass is fairly, "pastoso" (Le. with a

paste-Iike viscosity), and bejore it hardens completely, that the glass

master can shape the object which will have all the rigidity oj a solid

body but recall the liquid by its transparence.

In order to obtain the liquid, the molten substance which, on

solidifying, will have the characteristics oj glass, one starts from raw

materials, of which about 70% by weight is made up oj sand (silica).

It can be said that glass is made essentially out oj silica which

therejore is called the "vetrificante" (glassmaking agent). The other

raw materials are added to keep the temperature oj jusion down:

1400°C jor present-day Murano glass, while silica alone has a melting

temperature oj 1700°C. The substances which allow this lowering oj

temperature are thus called "fondenti" (flux or melting agents).

Typical is soda ash. The sodium oxide present in the glass modifies

the characteristics oj the glass obtained considerably, particularly in

its workability and in the chemical resistance oj its surjaces. The more

sodium oxide there is in the glass, the slower it solidifies. (It is said

that the glass is "lungo", long). Slow hand working requires a glass

whicn is "long" enough and which must therejore contain enough

sodium oxide. The amount oj sodium oxide must not be excessive,

however, otherwise the glass becomes opaque on the surjace in

reaction to the atmospheric humidity. To contain this tendency,

limestone or calcium carbonate is used. Calcium, too, lowers the

melting point and is therejore a "flux", but since il also limits the

tendency towards opacity, il is called a "stabiliser", in that it makes

the surjace of the glass stable in relation to atmospheric humidity, To

have a sodium glass which retains its characteristics of trasparency

over time, a certain quantity of calcium is necessary.

Other raw materials which are added to the batch of silica, soda ash

and limestone are nitrate and arsenic, which have a "refining" action;

that is they facilitate the elimination of bubbles from the liquid and

improve its homogeneity. With these raw materials the transparent

colourless glass known as "Murano crystal" was obtained from about

14500n.

With the addition of small quantites of colouring or opacifying

substances to the raw materials mentioned, coloured or opal glass is

obtained.

The raw materials used today have to be very pure. The sand, in

particular, must not have more than 0.01 % of iron in it, otherwise

the glass will emerge blue-green. No common beach sand, then, for

glassmaking, but pure quarry sand, even though today the colouring

produced by iron can be avoided by using small quantites of

decolourisers (selenium, cobalt, neodymium, manganese) which,

however, in reducing colouration also reduce transparency.

The purity of the soda ash used today is assured by the industriai

process with which it is obtained. This is the "Solvay " process,

named after its inventor. It substituted the Leblanc process about the

middle of the last century when the latter had been in use for 50

years.

The other materials used today are also obtained either through

industriai processes or directly from the quarry at a level of purity

which is also compatible with costs. The homogeneity and the

transparency of fine blown Murano glass today are definitively

guaranteed by the purity of the raw materials and the glass-melting

methods, that is the possibility of reaching furnace temperatures of

over 1400°C, thanks to rich fuels sucn as methane.